How is Instant Coffee Made? A Look at the Production Process June 29, 2024 – Posted in: coffee – Tags: #BrewingCoffee, #CoffeeProduction, #FreezeDrying, #GrindingCoffee, #InstantCoffee, #RoastingCoffee, #SprayDrying

Instant coffee, a convenient and popular beverage choice for many, undergoes a fascinating process to transform freshly brewed coffee into a soluble powder that dissolves quickly in water. Here’s a detailed look at the production process behind instant coffee:

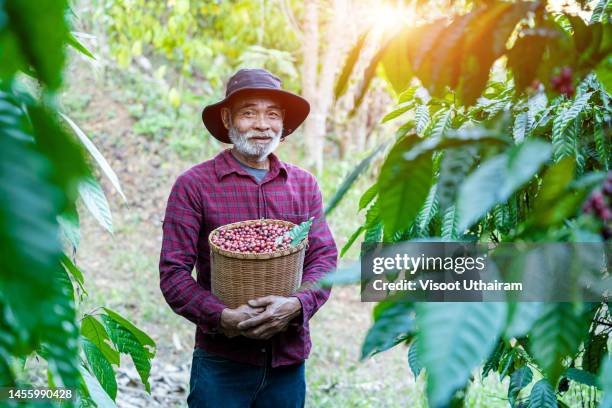

1. Starting with Quality Beans

The journey of instant coffee begins with selecting high-quality coffee beans. Typically, Robusta beans are preferred due to their higher caffeine content and ability to withstand the processing methods involved. However, some blends may include Arabica beans for their flavor complexity.

2. Roasting

Once selected, the beans are roasted to perfection. Roasting not only enhances the flavor and aroma but also prepares the beans for the subsequent steps. The beans are roasted at precise temperatures and durations to achieve the desired flavor profile.

3. Grinding

After roasting, the beans are finely ground into coffee grounds. The consistency of the grind is crucial as it affects the extraction process and the final flavor of the coffee.

4. Extraction

The ground coffee is then brewed to extract the coffee solids and flavor compounds. This step involves hot water passing through the coffee grounds, creating a concentrated coffee extract.

5. Concentration

The extracted coffee is then concentrated to remove water content, typically through methods like freeze-drying or spray-drying:

- Freeze-Drying: The concentrated coffee extract is frozen into slabs and then broken into granules. These granules are then dried under vacuum to remove the ice (sublimation), leaving behind coffee granules.

- Spray-Drying: Here, the concentrated coffee is sprayed into a hot air chamber. The droplets quickly dry into fine powder as they fall, which is then collected.

6. Instantization

To ensure the coffee dissolves easily in water, it undergoes an “instantization” process. This involves further drying and sometimes agglomerating the powder to create uniform particles that readily dissolve.

7. Packaging

Finally, the instant coffee is packaged into jars, sachets, or other forms suitable for consumer use. Packaging is crucial to maintaining freshness and flavor until the product reaches the consumer.

Benefits

- Convenience: Instant coffee offers quick preparation, making it ideal for busy lifestyles.

- Long Shelf Life: Due to its low moisture content, instant coffee can be stored for extended periods without losing quality.

- Versatility: It can be used in various recipes, from hot beverages to desserts.

Understanding the production process of instant coffee helps appreciate the effort and technology involved in delivering a satisfying cup of coffee. For a deeper dive into the history and evolution of instant coffee, check out our previous blog post on this fascinating topic!

Conclusion

The production of instant coffee involves a series of precise steps aimed at preserving the flavor and aroma of freshly brewed coffee in a convenient form. Understanding this process helps appreciate the effort and technology involved in delivering a satisfying cup of instant coffee to consumers worldwide. Whether enjoyed on its own or as part of a recipe,continues to be a beloved choice for coffee enthusiasts everywhere.